Product information

Performance highlights

◆ Can be used in primairy, secondary, tertiary or quarternary crushing

◆ Designed to crush the toughest of rock and ore

◆ Feed size up to 185 mm (7”)

◆ C.S.S min. - max. 6 - 38 mm (2/10”-1 5/10”), depending on crushing chamber configuration

◆ Capacity up to 208 tonnes / hour

◆ Hopper 8 m³ (10 yard³)

◆ Other configurations possible with different crushing chambers

◆ Diesel / electric drive

◆2 speed track drive

◆ Optional pre screen 1.200 mm (4’) x 1.800 mm (6’) *not available in the United States

◆ Optional 3-deck screen 3.600 mm (12’) x 1.500 mm (5’)

◆ Effective screen area 5,4 m² on each deck, with return conveyor

◆ Best product shape

◆ Extensive option list to configure to your application

Removable engine /generator compartment

Specifications

Transport dimensions | Transport dimensions with after screen | Working length without after screen | Working length with after screen | |

Weight | 38 t (41 sT) | 46 t (50 sT) | ||

Length | 14,475 mm (47’6”) | 18,500 mm (60’8”) | 19,400 mm (63’8”) | |

Height | 3,450 mm (11’4”) | 3,450 mm (11’4”) | 4,100 mm (13’5”) | 4,765 mm (15’8”) |

Width | 3,000 mm (9’10”) | 3,000 mm (9’10”) | 3,450 mm (11’4”) | 11,100mm (32’10”) |

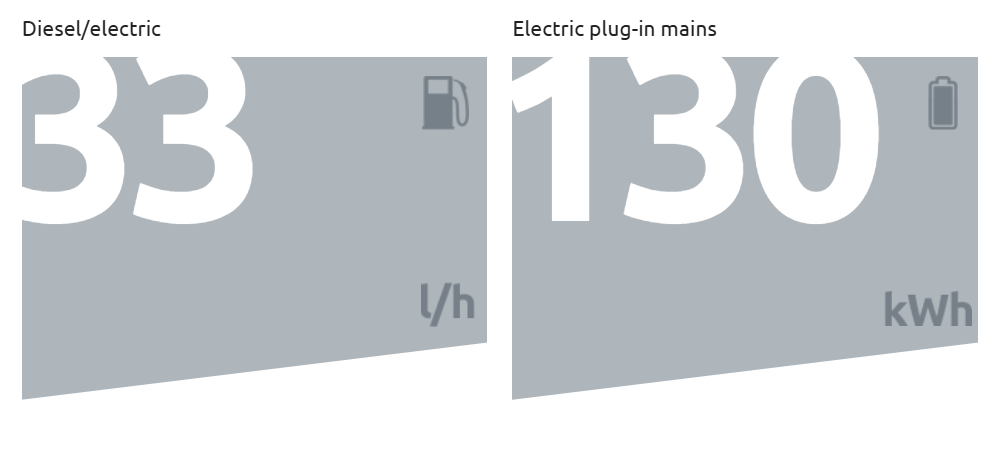

Fuel efficiency

Applications

◆ Abrasive and hard stone

◆ Hard rock and ore

◆ Granite and basalt

◆ Primairy, secondary, tertiary or quaternary crushing

◆ River and sea gravel

◆ Quarrying and mining

◆ Production of aggregates for asphalt, concrete and others

Cost savings

The quality of our machines mean they earn you more by working harder for longer, while keeping operational costs to the absolute minimum.